Pyrolysis Machine

- Commodity name: Pyrolysis Machine

- Capacity Model: 5TPD,8TPD,10TPD, 12TPD, 15TPD, 18TPD

- Raw material: Waste Tyre, Waste Rubber, Waste Plastic, Waste Oil Sludge, Waste Aluminum Foil, Waste Cable, Waste Leather, Waste Acrylic(PMMA), etc.

- End Production: Pyrolysis Oil, Carbon Black, Steel Wire

Category:

Details

Pyrolysis equipment is a facility that use the process of pyrolysis to convert organic materials like plastic or rubber into valuable products such as carbon black, oil, steel-wire and syngas.

Product Description

The feedstock is organic solids includes waste tyre, waste rubber (like used rubber cable, used soles), waste plastic, acrylic/PMMA, oil sludge, oil shale and so on.

It is available to choose batch-type and continuous type runing machines except for plastic.

|

SPECIFICATIONS FOR WASTE TYRE PYROLYSIS MACHINE

|

|||

|

Capacity

|

5TPD, 6TPD, 8TPD, 10TPD, 12TPD, 15TPD, 18TPD | ||

| Reactor Material |

Q345R, Alloy Steel, Stainless Steel

|

||

| Reactor Thickness |

16.45mm/18mm/20mm

|

||

| Total Weight | 30-40 tons (Varies by Design and Capacity) | ||

|

Heating Fuel

|

Fuel Oil, Natural Gas, Electric, Coal, Firewood

|

||

| Labor Qty Require | 2-4 Persons for per set machine, more machine, fewer labors | ||

| Processing Time | Feeding 2 hours, Processing 8-9 hours, Carbon Black and Steel Wire Discharging 1.5 hours. (Take 12TPD capacity as example) | ||

| Working Power | 15-30KW(Varies by Design and Capacity) | ||

1) Raw Material can be used for Pyrolysis machine

2) End Products (Feedstock is waste tyre)

3) If feedstock is plastic, the end products as below:

|

No.

|

End Products

|

Yield

|

Usage

|

|

1

|

Plastic Oil

|

20- 90% | * Sell directly. * Further refining to get standard diesel and gasoline via Zhongming distillation machine. * Use as fuel for heating pyrolysis machine or distillation machine. |

|

2

|

Carbon Black

|

4-74%

|

* Sell directly the char that can be used as a raw material for the production of activated carbon as well. * Further Refine carbon via carbon black refining machine. * Make pellet via carbon pellet maker. |

|

3

|

Non-Condensible Gas

|

6%

|

* Recycle as fuel through gas burner system(we supply gas burner for free). * Extra gas also can be storage as fuel for other heating. |

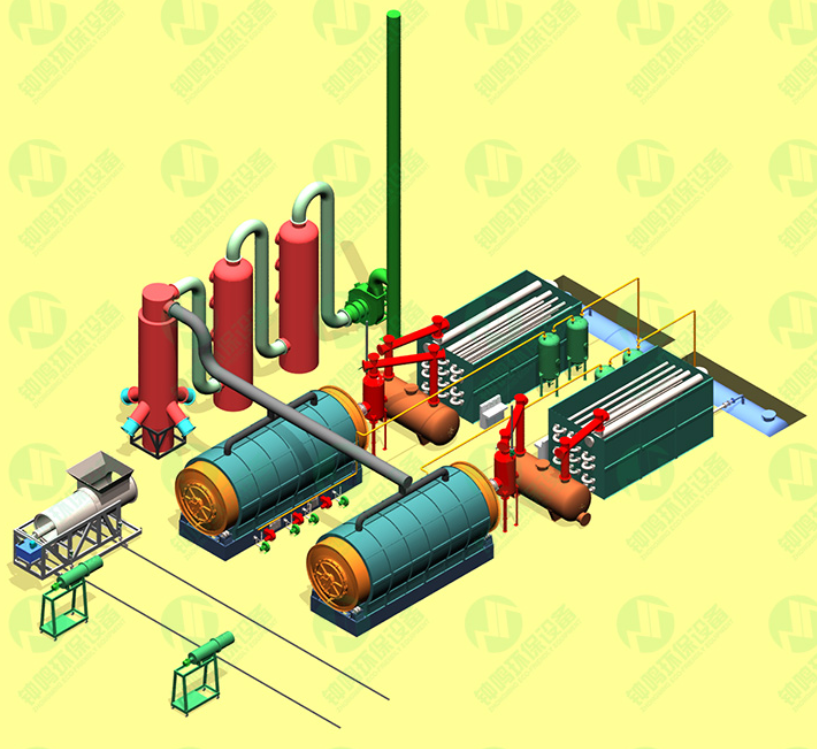

Layout Drawing

Here is a general overview of how a tire pyrolysis plant works:

1. Feedstock preparation & feeding:

Waste tire are collected and transported to pyrolysis plant, which are usually shredded or chopped into smaller pieces to facility the pyrolysis process. Hydraulic feeder is optional part, it can save labor cost.

2. Pyrolysis reactor:

The shredded tires are fed into a pyrolysis reactor by manual or hydraulic feeder, the reactor is a high temperature and oxygen-free environment. The reactor can be of various of designs like this one horizontal rotary reactor, batch system.

3. Heating and pyrolysis:

The reactor is heated to a high-temperature (typically between 300 to 450 degree celsius), causing the tires to undergo pyrolysis. In the absence of oxygen, the organic components of the tires breakdown into gases, liquids and solids residues.

The heating base designed based on the fuel types that can be coal, natural gas, pyrolysis oil, diesel.

4. Gas cooling and condensation:

The gases produced during pyrolysis, such as syngas and hydrocarbons are cooled and condensed into liquid form. The liquid fraction are commonly referred to as pyrolysis oil or say tire oil.

5. Solid residue collection:

The solid residue left after pyrolysis is primarily composed of carbon black and steel wires. The carbon black can be used as a valuable industrial material, the steel wire can be recycled.

6. Product separation and refining:

The products obtained from pyrolysis (pyrolysis oil. carbon black and steel wire) are separated and refined. The pyrolysis oil may undergo further processing to remove impurities and obtain a higher quality fuel.

7. Products utilization:

The end products such as pyrolysis oil, carbon black and steel can be used for various purposes:

Pyrolysis oil can be used as a fuel in industrial boilers (like power plant for heating steam-generator), cement factory, lime factory, glass factory, paper factory; the pyrolysis oil also can be refined then put it into machinery (low-speed motor like agricultural machinery, forklift, tractor...) but not automotive gas oil and automotive diesel, because of the sulfur content and cetane number.

Carbon black has applications in the rubber industry, as a pigment, or as a reinforcing agent, or as the raw materials of other rubber products.

Steel wires can be recycled.

Syn-gas, it is able to be used for heating the reactor to save the fuel; excess gas can be stored into a balloon bag temporarily for use next production.

8. Emission treatment system (optional)

It is an optional part. Different countries, different environmental policies. If you need, please contact with our sales staff.

9. Return on investment of waste tyre pyrolysis project based on Central Asia market (take ZMLJ-I-10 with 10tons capacity as an example)

| Item Introduction | Details |

Unit Price /USD |

Quantity | Amount/USD | More | ||

| Description | Unit | ||||||

| Fixed investment | Pyrolysis machine | set | 69,800 | 1 | 69,800 |

different price with different capacities |

|

|

Transportation cost by land |

set | 26,000 | 1 | 26,000 | flat-bed trucks | ||

| Customs tax 12% | set | 8,376 | 1 | 8,376 | |||

| Installation cost | |||||||

|

Technician's salary |

set | 100 | 20 | 2,000 | Check more details with sales | ||

| Round-trip air-tickets | each | 3,200 | 1 | 3,200 | |||

| Visa's fees | each | / | 1 | 0 | |||

| Local welder | day | 50 | 20 | 1,000 | Two welders needed | ||

| Local plumber | day | 30 | 10 | 300 | |||

| Labors | day | 20 | 20 | 400 | |||

| Crane forklift | day | 80 | 10 | 800 | |||

| License | / | each | 800 | 1 | 800 | ||

| Workshop | / | m2 | 100 | 500 | 50,000 | ||

| Operating cost | Water | m3 | 0.1 | 3 | 0.3 | ||

| Electricity | KW | 0.2 | 400 | 80 | |||

| Fuel(pyrolysis oil) | ton | / | 0.8 | 0 | Self-sufficiency | ||

| Labor | person | 20 | 3 | 60 | Manual feeding | ||

| Maintence | day | 50 | 1 | 50 | |||

| Depreciation cost | day | 24 | 1 | 24 | |||

| Daily income | |||||||

| Products prices | Tyre oil | ton | 480 | 4.5 | 2,160 | 45% of input | |

| Steel wire | ton | 242 | 1.5 | 363 | 15% of input | ||

| Carbon black | ton | 104 | 3 | 312 | 30% of input | ||

10. How does the pyrolysis machine work?

Please check bellow links:

1) Animated video of pyrolysis machine (taking as plastic as an example)

https://www.tiktok.com/t/ZP8Yhvb4N/

2) Pyrolysis carbonization plant used for treatment the oil sludge from oil fields

https://youtube.com/shorts/DIaaM5ENIH4

3) Totally 8 lines of waste tire pyrolysis carbonization machines

https://youtube.com/shorts/8XX3JJ6A5To

4) Shipped 10 lines of waste plastic to diesel oil plants to Korea

https://youtu.be/Je4Gu6A2aWo

Key words:

Related Products

Inquiry

*Note: Please be sure to fill in the information accurately and keep the communication open, we will get in touch with you as soon as possible